Plexiglass is a lightweight, transparent plastic frequently used as a break-resistant substitute for glass. It is commonly seen in show cabinets, windows, and safety obstacles. Cut Plexiglass Sheets to exact measurements is essential for various applications since it guarantees functionality and safety.

This article will explain what Plexiglass is, discuss its many applications, and explain why cutting it to precise measurements is necessary for general and specialty applications.

Types of Plexiglass

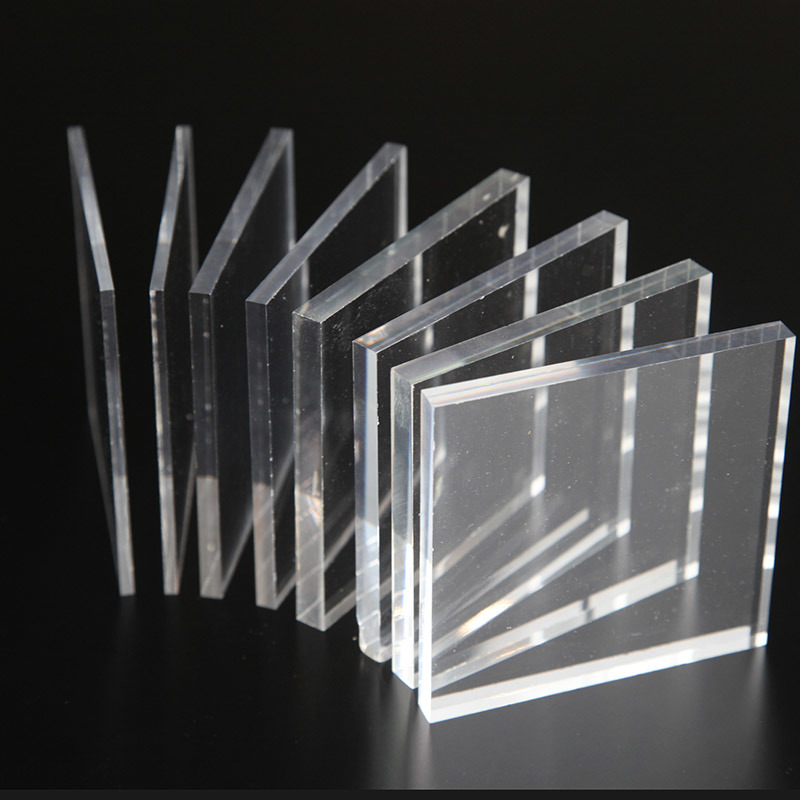

Clear Plexiglass

Plexiglass’s versatility is genuinely remarkable. Its clear variant, with its superior transparency and clarity, is a lightweight and shatter-resistant alternative to regular glass. Whether for picture frames, aquariums, windows, or safety obstacles, Plexiglass offers a clear view while ensuring longevity and safety.

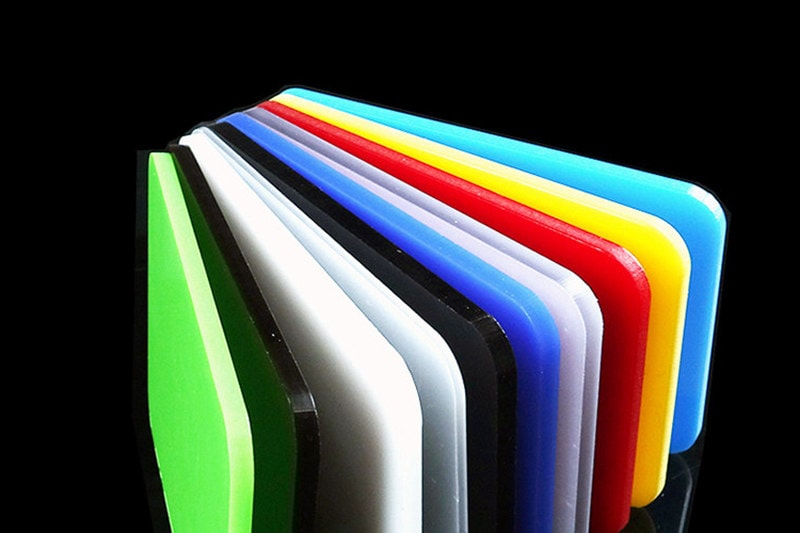

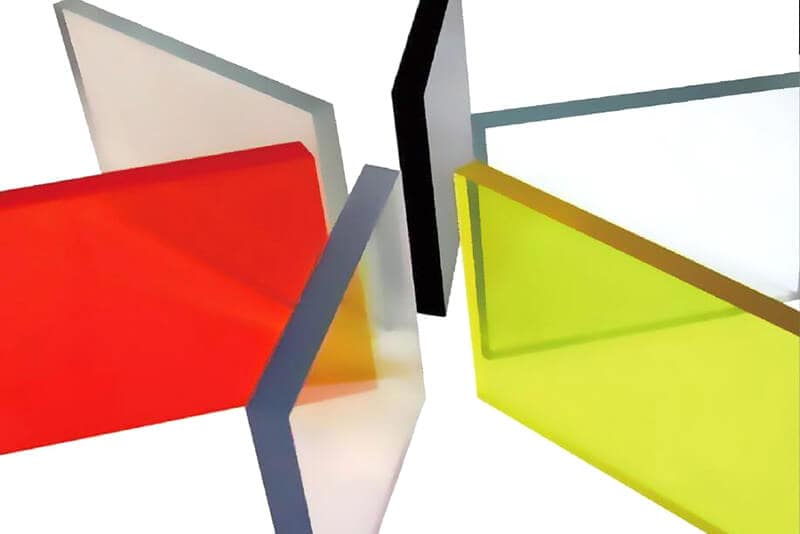

Colored Plexiglass

The variety of colors and tints in colored Plexiglass enhance the projects’ visual appeal. It provides beauty and durability and is used for creative displays, signage, and decorative panels.

Frosted Plexiglass

The matte texture of frosted Plexiglass diffuses light to provide seclusion while letting light through. It combines practicality with a fashionable appearance and is frequently used for ornamental features, office dividers, and bathroom windows.

UV-resistant Plexiglass

UV-resistant Plexiglass tolerates long periods of sun exposure without causing yellowing or degradation. It ensures long-lasting clarity and durability under intense sunlight, making it simple for outdoor applications such as greenhouse panels, signage, and skylights.

Benefits of Custom-sized Plexiglass

Custom-sized Plexiglass has many advantages for a range of uses.

- First of all, it guarantees an exact fit for particular projects, which is essential for both performance and safety.

- It’s an economical option because you only order what you need, which minimizes material waste.

- Custom sizing improves a project’s appearance and usefulness by enabling a customized appearance that satisfies particular design specifications.

- Custom-sized Plexiglass offers a practical and aesthetically pleasing option for commercial, industrial, or domestic applications.

Applications of Custom-sized Plexiglass

Home Improvement: Perfect fit, increased durability, and a sleek, contemporary look are the main benefits of using custom-sized Plexiglass for projects like windows, shelves, and furniture.

Commercial Use: Custom Plexiglass is used for dividers, signage, and displays in commercial settings. It gives businesses a polished appearance, is long-lasting, and allows them to design distinctive, branded spaces.

Arts and Crafts: Custom Plexiglass is a popular material for arts and crafts projects. It enables enthusiasts and makers to precisely build personalized things for practical use, art, or home décor.

Architectural Design: Custom-sized Plexiglass is utilized for skylights, fences, and facades in architecture to optimize light, improve aesthetic appeal, and guarantee structural integrity.

Industrial Use: Plexiglass cut to size is crucial as safety barriers and machine guards. It protects workers and equipment, maintains visibility, and adheres to regulations, showcasing its versatility and importance in various industries.

How to Measure for Plexiglass

Instruments Required for Precise Measurement

- Measurement tape

- Ruler or straight-edge

- Marker or pencil

- A notepad to take measurements

How to Measure Dimensions

Precision is critical when measuring for Plexiglass. Always use measuring tape to measure the width and length of the space where the Plexiglass will be installed, ensuring that you measure twice for accuracy.

- Measure Obstructions: Note any irregularities or obstructions that could compromise the fit. To obtain exact dimensions, measure the area surrounding these.

- Verify Squareness: Measure diagonals to ensure corners are at the correct angles. Equal diagonal lengths indicate a square or rectangular space.

- Take Thickness Into Consideration: Determine the required Plexiglass thickness based on the intended use, then take the appropriate measurements.

- Take Note of Measurements: You prevent confusion when cutting, so write down all measurements precisely or accurately.

Points to Ensure Your Measurements Are Accurate

Use Best Equipment: Ascertain the accuracy and dependability of your straight edge and tape measure.

Tolerances: For the Plexiglass to fit correctly, allow a minor tolerance, usually 1/8 inch.

Measure in the same units: Use the same measurement units (centimeters or inches) every time and throughout the procedure. Enlisting the assistance of a second person is advisable to ensure accurate measurements and handling in more significant areas.

Cutting Plexiglass to Size

It’s essential to prepare the Plexiglass carefully before cutting it to size. Score the Plexiglass with a straight edge using a sharp utility knife or specialty acrylic cutting tool. Once the sheet has been scored, gently snap it along the cut line, ensuring a clean and precise cut. Cut Plexiglass Sheets to your exact size. For curved cuts, use a jigsaw with a plastic-specific fine-tooth blade. To smooth the edges, softly sand them with fine-grit sandpaper. When cutting Plexiglass, always wear safety goggles and operate in an area with good ventilation.

Where to Get Plexiglass Cut to Size

Local Hardware Stores: Many hardware stores offer Plexiglass cutting services. They can cut sheets to the exact measurements you provide.

Specialized Fabricators and Suppliers: Businesses specializing in acrylic and plastics frequently offer custom cutting services. These professionals have material selection skills and can manage intricate projects.

Online Retailers and Services: Custom-cut Plexiglass is available from various online retailers and services. You can order sheets online and have them delivered to your door precisely to your measurements.

Cost Factors for Custom Plexiglass

Cost of Materials

Plexiglass sheets vary in price according to their thickness, size, and quality. Thick, premium sheets are more expensive, but the cost per unit may be lower with bulk purchasing.

Charges for Cutting and Finishing

These costs are determined by how precise and intricate the design must be. Fine finishing and custom shapes drive up the price. A few businesses provide package discounts for several trims.Cut Plexiglass Sheets to your exact size.

Charges for Shipping and Handling

The Plexiglass’s weight and size have an impact on these expenses. The shipping price for larger or heavier items is higher. Special packaging may also be required for fragile objects.

DIY vs. Professional Services Comparison

While it takes tools and expertise, DIY projects can save money. Errors may be expensive. Although they cost more, professional services offer accuracy and experience. Decide according to your means and capacity.

Conclusion

Numerous advantages come with custom-sized Plexiglass, including improved durability, a polished appearance, and a perfect fit. It saves time and effort to Cut Plexiglass Sheets for you. Whether for protective barriers, windows, or displays, bespoke solutions guarantee accuracy and excellence. You may get the most significant outcomes for your projects and enhance both usefulness and beauty by selecting custom Plexiglass.