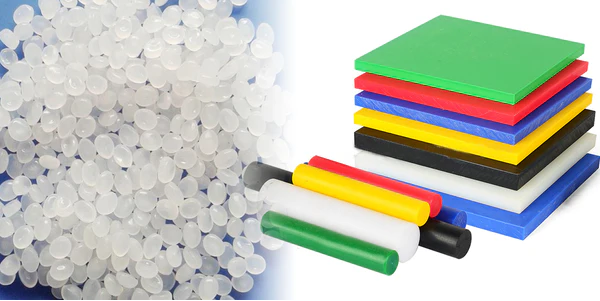

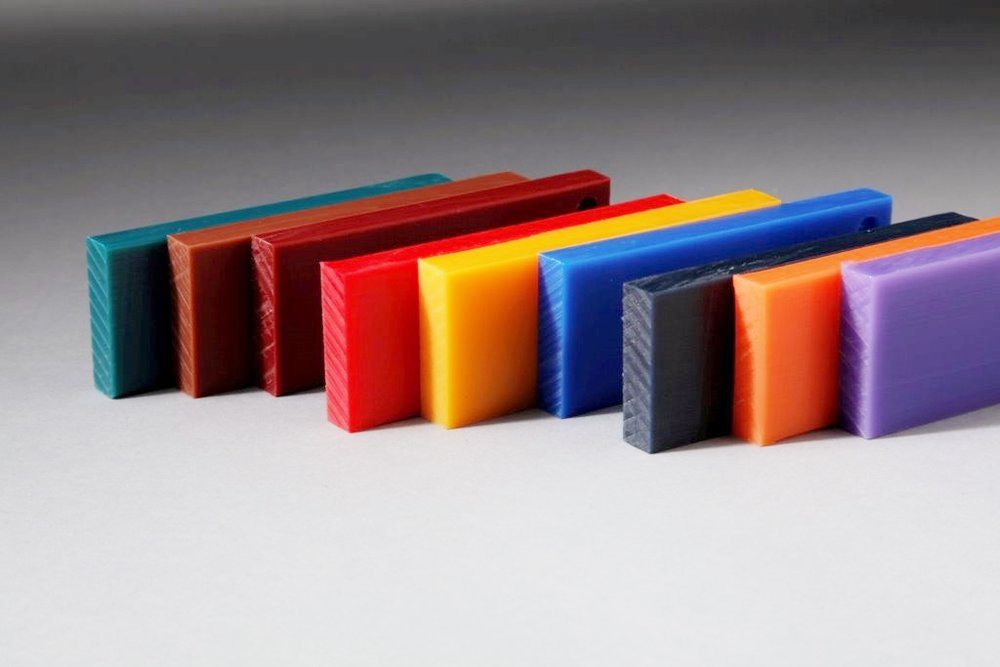

One kind of plastic with a reputation for outstanding toughness and adaptability is UHMW Polyethylene Sheets. Ultra-high molecular weight polyethylene (UHMWPE) offers exceptional durability and minimal friction, making it ideal for various industries. Its remarkable strength and lightweight nature ensure it excels in applications requiring both durability and impact resistance.

Because of its distinct molecular structure, UHMW polyethylene provides dependable performance for anything from industrial machinery components to medical devices and even sports equipment. For more detailed information and applications, visit this link.

Working Of UHMW

Low Friction: UHMW polyethylene is perfect for sliding parts and conveyor belts because its smooth surface lowers friction.

High Impact Strength: It is suitable for machine guards and bumpers, it can sustain substantial impacts without breaking.

Chemical Resistance: It is helpful in chemical processing equipment and can withstand chemical corrosion.

Abrasion Resistance: Suitable for bearings and gears, its complex surface withstands wear from rubbing and scraping.

Noise reduction: Used in automotive and industry parts, it dampens noise because of its damping qualities.

Food safe: Non-toxic, permitted for use in food processing and packaging, and acceptable for contact with food.

Properties of UHMW

High Impact Strength: Ultra-high molecular Weight, or UHMW, polyethylene is renowned for its exceptional resistance to impact. This makes it appropriate for uses where toughness is crucial, such as machinery parts and conveyor systems.

Minimal Friction: Its extremely low coefficient of friction minimizes wear and energy consumption in sliding applications such as gears and bearings.

Chemical Resistance: UHMW PE is perfect for chemical processing tanks and equipment since it is resistant to various chemicals, acids, and bases.

Excellent Abrasion Resistance: In high-wear situations like chute liners and conveyor belts, its robust surface resists abrasion, extending the life of components.

Application of UHMW

Industrial Machinery: Due to its excellent abrasion resistance and low friction, UHMW polyethylene is frequently used in industrial machinery components such as gears, wear strips, and bearings. This lowers maintenance costs and boosts operational effectiveness in the processing and manufacturing sectors.

Transportation: Manufacturers use UHMW PE in vehicle components such as skid plates, snowplow blades, and truck bed liners.

Medical applications: UHMW polyethylene’s durability and biocompatibility make it a popular choice for devices. Its strength, low friction, and chemical resistance also enhance prosthetics, knee and hip replacements, and surgical equipment, improving patient safety and reliability.

Sports and Recreation: Parts of skateboards, snowboards, and kayak hulls are examples of equipment used for sports and recreation that contain UHMW PE. Because of its lightweight design, impact resistance, and friction resistance, it is perfect for improving performance and longevity in various outdoor and sporting activities

Advantages of UHMW

- High Impact Strength: It is resilient in demanding applications because it can bear substantial impacts without shattering or deforming.

- Low Friction: Due to its smooth surface, there is less friction, which uses less energy and prolongs the life of machine parts.

- Chemical Resistance: It may be used in demanding conditions since it is resistant to various chemicals, acids, and bases.

- Abrasion Resistance: By preventing wear from abrasion, its durable surface increases the longevity of components.

- Self-lubricating: Requires less lubrication and maintenance because it is naturally lubricating.

- Lightweight: Less heavy than metals, making handling easier and lowering the total weight of applications.

- Noise reduction: By absorbing vibrations, noise is attenuated, resulting in quieter mechanical operation.

Disadvantages of UHMW

- Low Melting Point: Compared to other technical polymers, UHMW PE has a comparatively low melting point, which may restrict its use in high-temperature applications.

- Poor UV Resistance: If left untreated or unprotected, it will gradually deteriorate when exposed to continuous sunshine or UV radiation, impacting outdoor applications.

- Difficult to Bond: Because of its low surface energy, UHMW PE is difficult to bond with conventional adhesives and necessitates specialist methods like welding or mechanical fastening.

- Swelling in Hydrocarbon Solvents: Although UHMW PE is chemically resistant, exposure to some hydrocarbon solvents can cause it to swell or break down, affecting its chemical resistance in some situations.

- High Thermal Expansion: Its comparatively high thermal expansion coefficients may impact dimensional stability when temperature changes are substantial.

UHMW Characteristics

- Self-Lubricating: The molecular structure of UHMW polyethylene confers natural lubricating qualities, negating the need for additional lubricants.

- High Wear Resistance: In high-friction applications, its remarkable resistance to wear and abrasion allows it to retain its surface integrity.

- Low Water Absorption: UHMW PE absorbs very little water in damp or humid situations, keeping its mechanical qualities intact.

- Insulation Quality: Excellent electrical insulating qualities make it appropriate for electrical and electronic applications.

- Non-Toxicity: UHMW polyethylene ensures safety in delicate conditions because it is non-toxic and authorized for medical and food-contact applications.

Why choose the UHMW sheet?

The outstanding durability, minimal friction, and resistance to wear and impact are the reasons for using UHMW Polyethylene Sheets. Because of their capacity to save maintenance costs and increase efficiency, they provide dependable performance in various industries, including manufacturing, transportation, and healthcare. UHMW sheets are the perfect choice for applications needing durability, toughness, and little maintenance because of their excellent chemical resistance and lightweight design.

Conclusion

UHMW polyethylene sheets are solid and adaptable materials that work well for various uses. Thanks to their well-known high-impact strength, low friction characteristics, and chemical resistance, they provide dependable performance in multiple industries, including manufacturing and healthcare.

Conveyor belts, medical equipment, and automobile parts are among the components that favor them due to their durability and low maintenance expenses. UHMW polyethylene sheets, which are naturally durable and easily machined, offer practical solutions where durability, strength, and efficiency are crucial. This helps them perform better and last longer in a variety of settings.