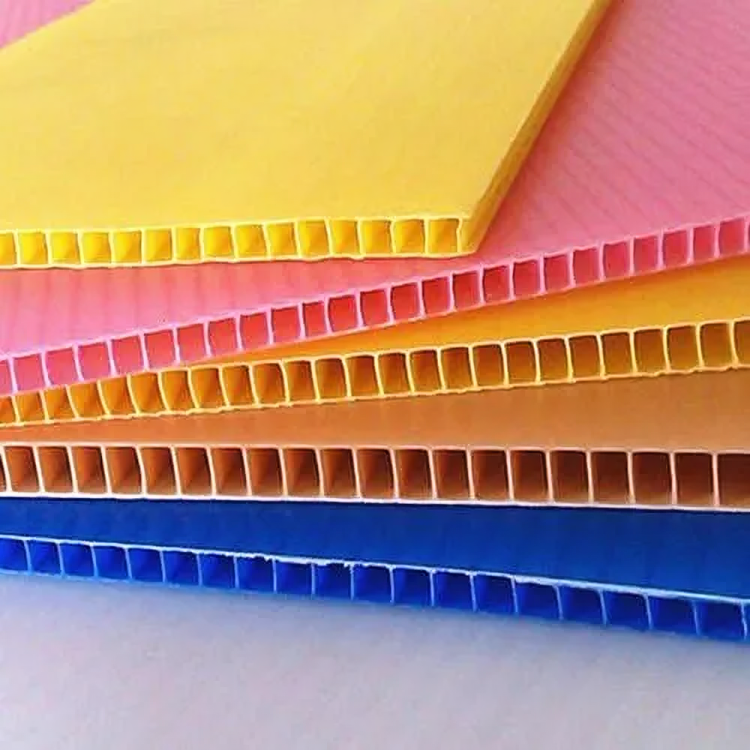

Polyvinyl chloride is used to create flexible PVC corrugated plastic sheets, renowned for being solid and lightweight. They have a unique wavy design that increases flexibility and strength. Because these sheets are inexpensive and have weather-resistant qualities, they are widely used in the roofing, signs, and packaging industries.

They offer a cost-effective option for various industrial and outdoor applications, providing impact and moisture resistance while being simple to handle and install. To explore more about PVC corrugated plastic sheets and how they compare to other materials, click here for an in-depth analysis. We’ll contrast PVC corrugated plastic sheets with different materials throughout the piece to help you grasp the advantages and disadvantages of each. We’ll wrap up by summarizing their real-world uses in several industries.

Properties of PVC Corrugated Plastic Sheets

PVC corrugated plastic sheets are very adaptable due to several vital characteristics they have:

- These sheets are appropriate for outdoor applications because they are weather-resistant and robust.

- PVC corrugated plastic sheets are lightweight despite their strength, making handling and installation easier.

- They are more resistant to damage from physical forces due to the corrugated structure’s improved impact resistance.

Manufacturing Process

PVC corrugated plastic sheets are manufactured using several methods.

- First of all, a mixture of additional additives and polyvinyl chloride (PVC) resin is prepared.

- After heating, the mixture is forced through a die to create flat sheets.

- The distinctive wavy pattern is produced by passing these sheets through corrugating rollers.

- The sheets are subsequently shaped to the required dimensions by cooling and cutting equipment.

- Just prior to pack the sheets for sale or to distribute, they are sent to the quality inspections for strength, flexibility and for uniformity.

- PVC corrugated plastic sheets are assured to fulfill industry standards for performance and durability in a range of applications.

Material

Stabilizers, plasticizers, and pigments are among the additives that are used to improve color, flexibility, and weather resistance. Together, these components provide sturdy, portable sheets appropriate for outdoor use.

Advantages of PVC Corrugated Plastic Sheets

Durability: PVC corrugated plastic sheets offer long-term performance in various applications since they are strong and wear-resistant.

Weather Resistance: They don’t weaken or deteriorate when exposed to sunlight, rain, or temperature fluctuations.

Lightweight: These sheets are lightweight and straightforward to handle, carry, and install despite their strength, which lowers labor and transportation expenses.

Chemical Resistance: They are suited for industrial and agricultural settings since they can withstand damage from acids, alkalis, and other chemicals.

Impact Resistance: Small collisions don’t cause cracks or fractures because of their corrugated structure, which absorbs impacts.

Cost-Effectiveness: PVC sheets are less expensive to buy and maintain than other materials, providing value over time.

Versatility: They are adaptable to various situations and requirements that are frequently used in roofing, signage, and packaging.

Applications

- PVC-coated plastic sheets are used in a wide range of industries. Because of their resilience to weather and longevity, they are frequently utilized in siding and roofing projects.

- Their lightweight design and capacity to retain vivid colors make them perfect for signs and advertising.

- Their ability to withstand moisture and impact benefits the packaging and transportation industries.

- These sheets are utilized for protective barriers and greenhouse roofs in horticulture and agriculture.

- Their versatility includes using them for do-it-yourself projects, temporary shelters, and protective layers in crafts and artwork.

- Due to their durability and flexibility, PVC corrugated plastic sheets provide valuable solutions in various industries.

Environmental Considerations

The following are the main areas of concern for PVC corrugated plastic sheets in terms of the environment:

Recyclability of PVC Materials: Although PVC is recyclable in and of itself, the corrugated structure of PVC sheets might make recycling procedures more difficult. To maximize the reuse of PVC materials, proper facilities for separation and recycling are necessary.

Aspects of Sustainability and Eco-Friendly Alternatives: Manufacturers are increasingly investigating eco-friendly production methods and additives to reduce their environmental effects. To help with sustainability initiatives, look for sheets branded with eco-certifications or constructed from recycled PVC.

Impact on the Environment and Disposal: Adequate disposal techniques are essential to keeping PVC waste out of landfills and ecosystems. Because incinerating produces hazardous fumes, it is best to avoid it. Recycling programs and ecologically friendly disposal techniques help lessen the negative effects on the environment.

If you want to know more about whether corrugated PVC roof panels are the right choice, explore here for a comparison of plastic versus metal roof sheeting.

Case Studies or Examples

The following are some instances of creative and practical usage for PVC corrugated plastic sheets:

Roofing Solutions: PVC corrugated sheets are a common roofing material for agricultural buildings and temporary constructions because of their strength and resilience to weather. Their lightweight yet protective characteristics are useful for greenhouses and cattle shelters.

Signage and Advertising: PVC corrugated sheets are frequently used for outdoor signage across a range of sectors. They are perfect for promotions because they can resist outside conditions and still display colorful graphics.

Packaging Innovations: These sheets are utilized in the packaging sector to make protective packaging and lightweight, substantial containers. During transit, they offer protection against impact and moisture and cushioning.

Future Trends

- PVC corrugated plastic sheet trends for the future are being shaped by a few significant developments:

- Research is still being done to improve PVC formulations for greater sustainability, such as by adding recycled material or bio-based additives.

- Innovations in production procedures improve product performance and minimize environmental effects.

- PVC corrugated sheets are growing in popularity as buildings require stronger, lighter materials.

- Smart building integration is one emerging application for these sheets, which could contain solar or sensor technologies.

- Difficulties include handling environmental issues related to the manufacture and disposal of PVC.

- There are opportunities to grow into new markets, such as those for noise barriers or solar panel backing in the renewable energy sector.

Conclusion

PVC corrugated plastic sheets are essential in many industries because of their strength, portability, and low weight. They are used as sturdy roofing materials in the building, practical signage options, and safe packaging for transit. Future developments in materials and technology should lead to improved performance and sustainability. These sheets will have prospects in the future for developing industries, including innovative building applications and renewable energy. PVC corrugated sheets are set to change as companies look for environmentally friendly alternatives.